Problem

Complex manufacturing operations demanding high precision and strict product defect control.

Solution

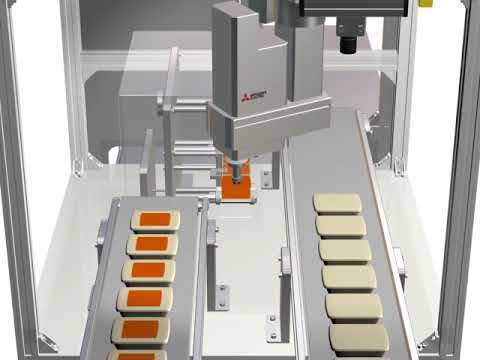

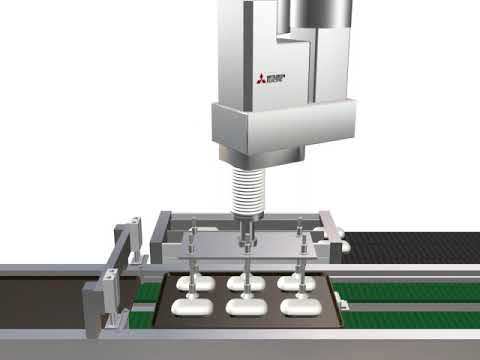

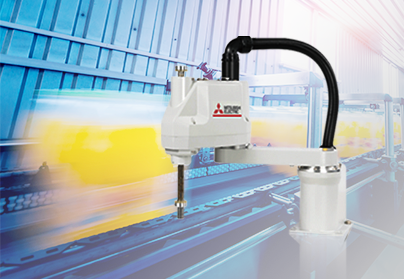

To solve this issue, Mitsubishi Electric proposes the MELFA FR Series Robots: SCARA Robot (6-12-20kg), F Series Robot (35-50-70kg); in combination with Mitsubishi Electric's PLC, inverter, and servo devices.

AI Robot benefits

High Speed

The robot's servo technology (vibration-free, high-speed, autotune, etc.) and specialized drive design will help to ensure stable operation at high speeds (up to 0.29s/cycle).

Food Safety Standards

The robot is suitable for using in cleanroom environments (ISO class 3) thanks to the ability to meet the safety requirements of food, pharmaceutical, and medical production (Standard - IP20/Oil mist - IP65).

Clever Jobs

The ability to automatically control force for tasks that require gentle handling of soft food items.

Case study

Mitsubishi Electric Recognized by GUINNESS WORLD RECORDS for the fastest robot to solve a puzzle cube

Assembly of Contactors in an Automatic - Smart Production Process with Mitsubishi Electric Robot