Building a seamless - fast - durable packaging process with smart automation solutions from Mitsubishi Electric

By integrating Mitsubishi Electric's factory automation solutions, businesses can create a seamless, highly efficient packaging process. Along with the application of Mitsubishi Electric's robot integrated on AGV, helping to transport goods between processes quickly, saving labor costs at the factory floor.

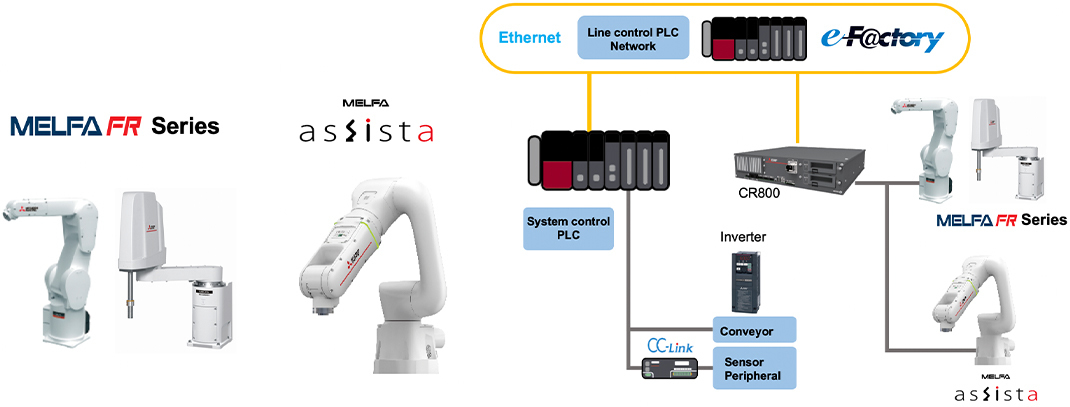

Optimal system configuration with smart automation solutions from Mitsubishi Electric, including:

- Industrial robot MELFA FR Series

- Collaborative robot MELFA ASSISTA

- System control PLC

- Controller for robot arm FR Series – CR800

- Inverter

- CC-Link communication network

|

Issues |

Solutions from Mitsubishi Electric |

|

Automation of lines with large transport volumes, simple transport and boxing tasks |

High-speed vision picking system. Automation with industrial robots including peripheral sensor equipment |

|

Collaboration between humans and robots |

Optimum layout by cooperative robot |

|

Loading and Unloading cargo to AGV |

Automation by mounting robot on AGV |

|

Prediction of robot failure time |

Preventive and predictive maintenance function |

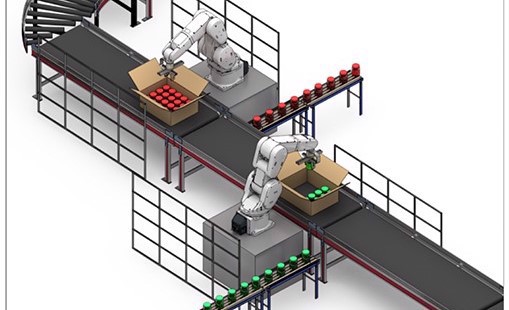

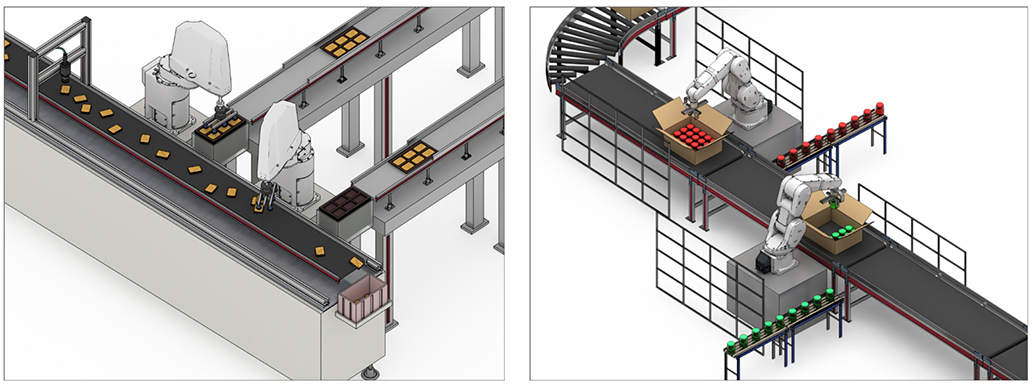

1. AUTOMATION OF LINES WITH LARGE TRANSPORT VOLUMES, SIMPLE TRANSPORT AND BOXING TASKS

Realization of Pick & Place and Boxing system by MELFA-FR series robot

In addition to automating the high-speed transfer and alignment of workpieces by a scalar robot, Boxing by vertical robot is realized by utilizing peripheral sensor equipment such as vision sensor.

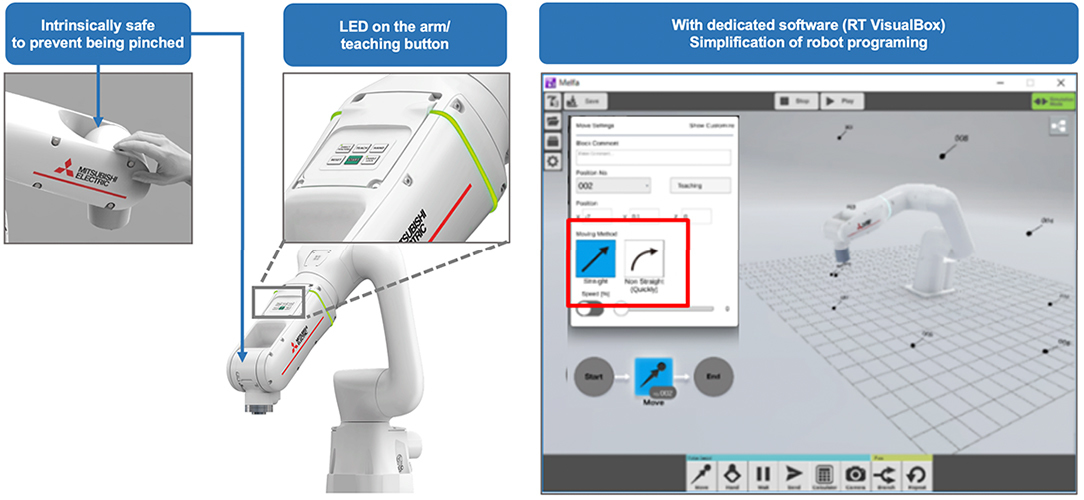

2. COLLABORATION BETWEEN HUMANS AND ROBOTS

Collaborative solutions that are easy to deploy by anyone, anywhere quickly.

- Rounded appearance for intrinsically safe design that prevents hands and fingers from being pinched and for reducing pressure in case of collision.

- Operation button mounted on arm instead of teaching box.

- Arm-mounted LEDs facilitate robot status monitoring.

- Visual programming on tablet screen makes robot programming unnecessary.

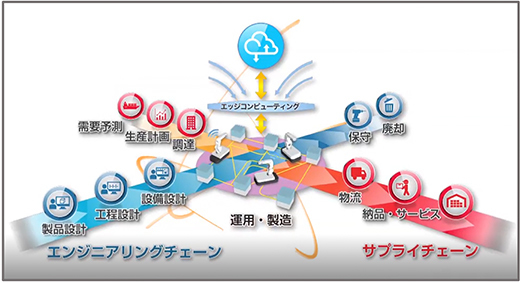

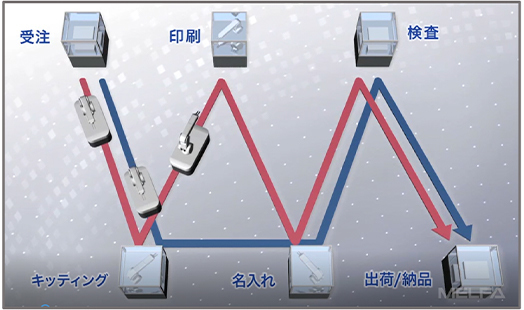

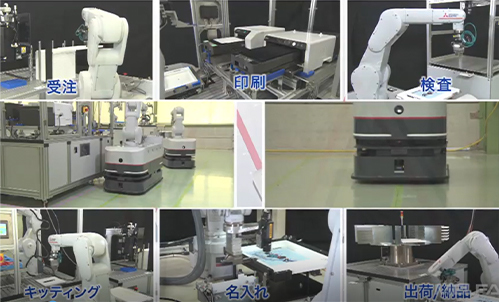

3. LOADING AND UNLOADING CARGO TO AGV

Efficient inter-process transportation can be realized by mounting a robot on AGV.

Collaborative robots are installed on AGVs to reduce labor costs for loading and unloading work. Production and quality information can be collected and managed in an integrated manner through the cooperation of high-level management systems.

|

AGV + Robot Exhibition |

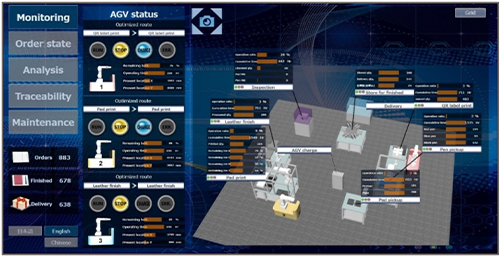

Image of cooperation between host systems and the field |

|

AGV + Robot Inter-process Conveyance |

AGV + robots in each process |

|

Production status monitor screen |

|

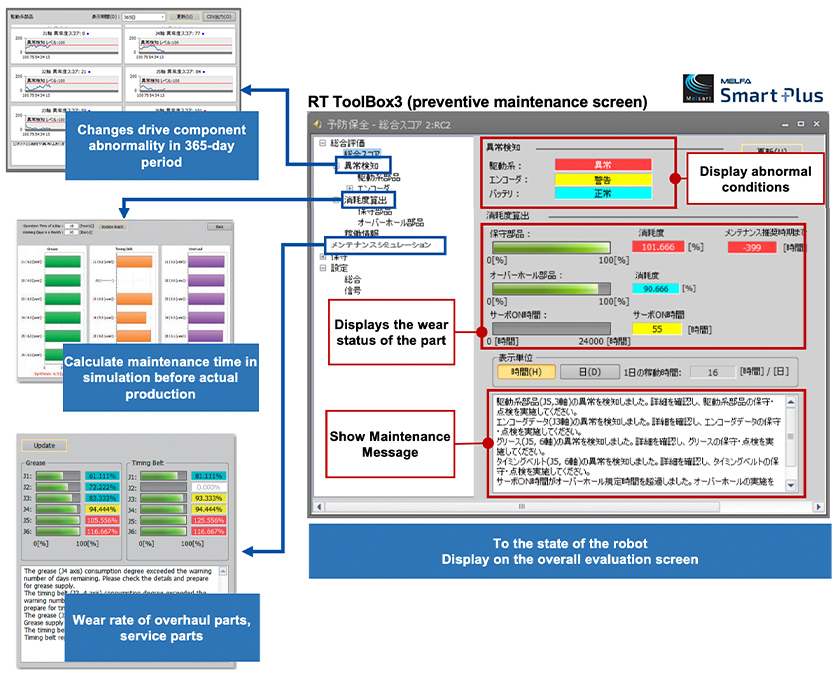

4. PREDICTION OF ROBOT FAILURE TIME

|

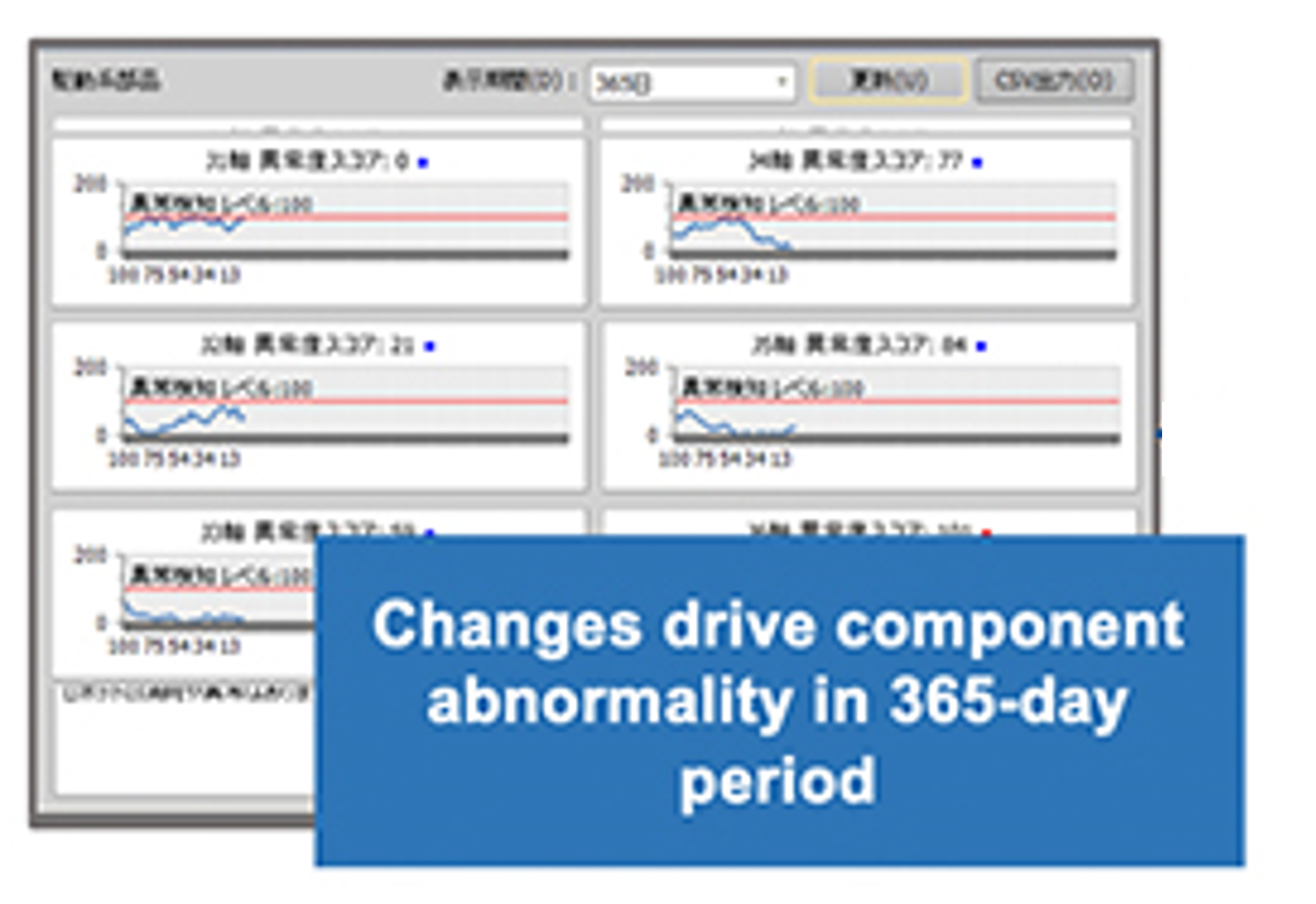

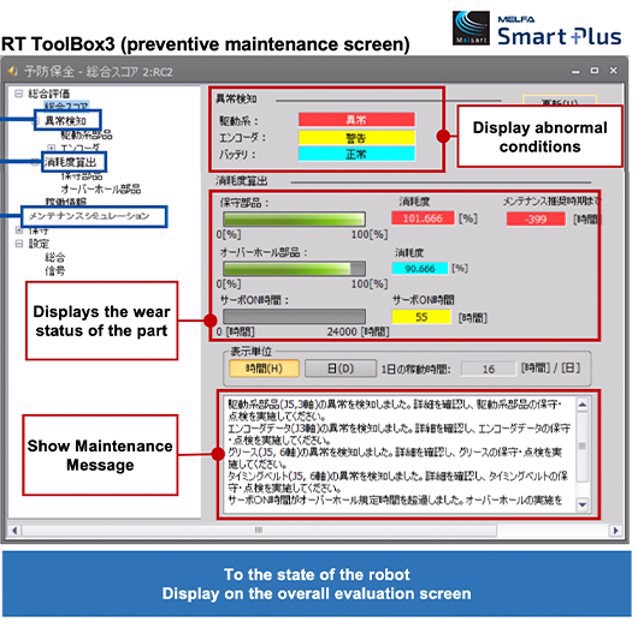

Early detection of abnormalities through continuous monitoring (Abnormality detection function) Using proprietary technology to detect signs of failure before a serious failure occurs. Enable maintenance and prevent equipment shutdowns (Reduction Gear and Encoder). |

|

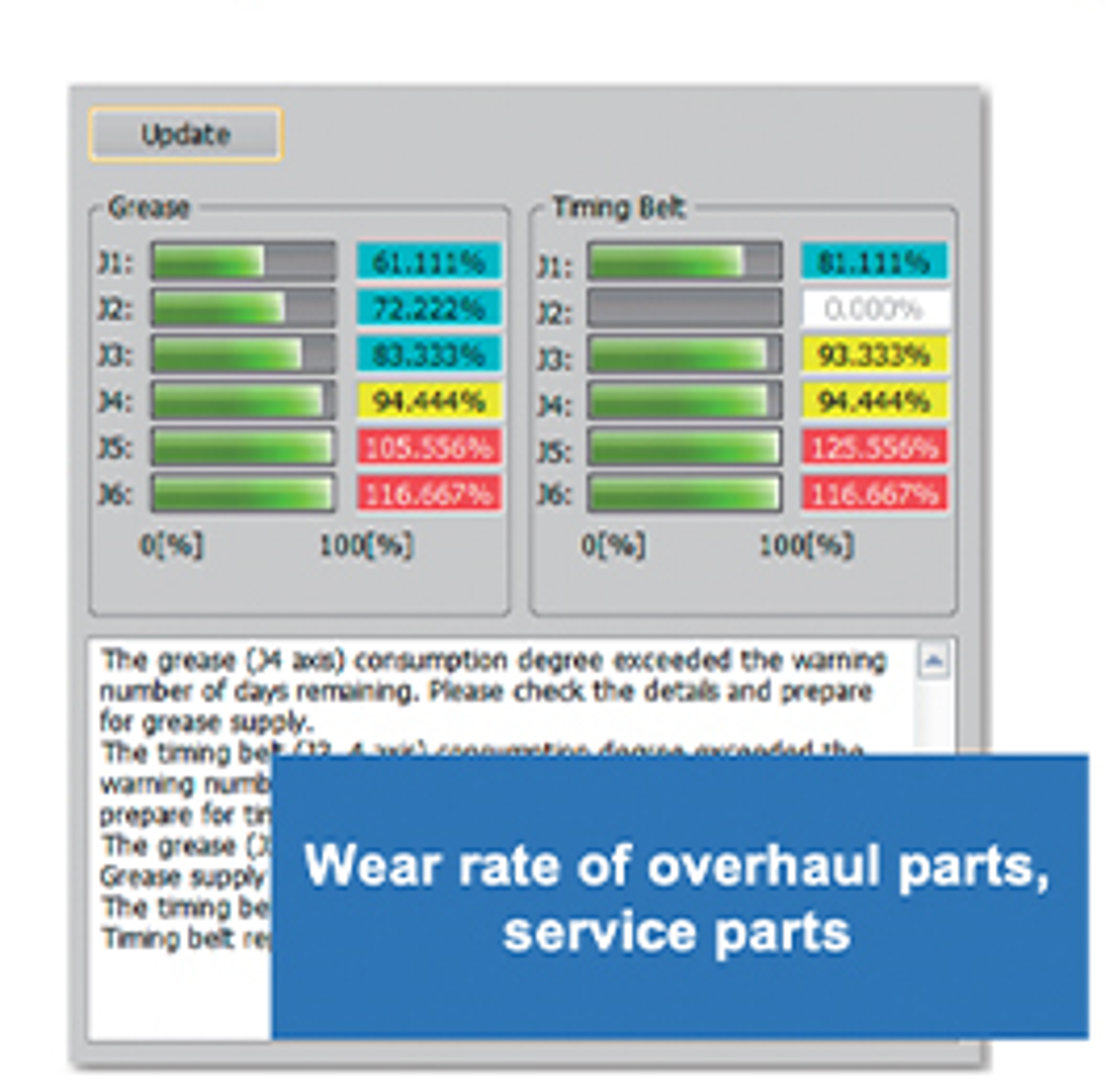

Check the wear rate of the drive parts (wear calculation function) The degree of wear of the driving parts is estimated from the operating state of the robot. Notification of maintenance timing (dedicated signal output and warning output), Support for efficient maintenance, including prioritization of maintenance (grease, belt, reduction gear, ball screw, bearing). |

|

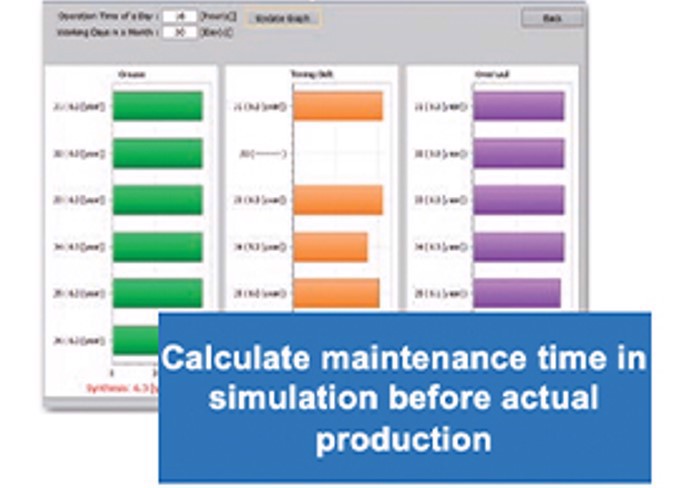

Simulation of wear and tear (Maintenance Simulation) Estimation of the replacement timing of maintenance parts and maintenance of overhauled parts, the maintenance cycle can be planned beforehand. It can also be used to verify the operation to extend the life of the robot. |

|

Supports construction of maintenance systems Various types of maintenance data can be used on robot programs, and can also be output to IT systems and GOT, supporting construction of maintenance systems suitable for customer equipment. |

5. PROMOTION OF AUTOMATION

- Smart picking achieved by robot-mounted AGVs and next-generation intelligent robots equipped with a vision sensor

- Operation monitoring and preventive maintenance realized by networking FA devices equipped on AGV