Mitsubishi Electric Vietnam organized a technology conference on Electrical Discharge Machines in Da Nang

On September 11th–12th, 2023, Mitsubishi Electric Vietnam held a technology conference on Electrical Discharge Machines in Da Nang.

This event with the theme: "Make connections, Create future", Mitsubishi Electric cooperates with the Vietnam Association of Supporting Industries (VASI) to share information, creating many opportunities for business cooperation.

Mitsubishi Electric Vietnam organized a technology conference on EDMs with the presence of delegates and guests.

The conference took place with the participation of Mr. Takashi Nishikuma – General Director of Mitsubishi Electric Vietnam, Mr. Nguyen Ba Tong, Vice Chairman of Vietnam Association of Supporting Industry (VASI)-The Chief Representative of Southern VASI, representatives of MEVN and all distinguished guests.

Mr. Takashi Nishikuma – General Director of Mitsubishi Electric Vietnam opening speech the conference.

Mitsubishi Electric is top of Factory Automation supplier in the World, and we have wide range production including EDM, Robot, Laser processing machine, PLC, and Drive products etc. Mitsubishi Electric conducted a conference to introduce Electrical Discharge Machines technology, realizing the significance of high technology in the manufacturing industry.

Mr. Huynh Trong Viet -Assistant Manager of Factory Automation Mechatronics of Mitsubishi Electric Vietnam presented overview of Mitsubishi Electric and EDMs product.

Vietnam is a high potential market with fast growing of economy and a great number of young and skilled workers, demand for quality products is also an urgent need in the integration process.

Mitsubishi Electric Corporation decided to invest more in this market by establishing Mitsubishi Electric Vietnam in July 2011 and officially expanding Factory Automation in April 2013.

Mr. Huynh Tan Thanh -Senior Executive of Factory Automation Mechatronics of Mitsubishi Electric Vietnam presented EDMs technology.

Furthermore, the EDM machines from Mitsubishi Electric Vietnam are fully equipped with the latest technology and integrate a smart design with high performance and durability, increase precision energy efficiency, and user-friendly. In consequence, Mitsubishi Electric's EDM equipment would significantly improve factory productivity and quality throughout production operations.

Wire cut EDM- MV series.

Wire cut EDM- MV series.

- Automated Wire Threading: Wire break point insertion is greatly improved for thick workpieces.

- Machining accuracy: Equipped with a linear shaft motor (LSM). Circular accuracy within 1µm is realized using optical drive system (ODS).

- Improved productivity: Surface roughness improvements are realized through enhanced power supply performance for high-speed machining.

- Energy savings, low operating cost.

- User-friendly

- D-CUBES Controller: Opening the door to IoT.

In order to keep up with the science and technology trends of the new era, D-CUBES is best utilized to improve machining precision, leverage IoT technology to boost productivity, and develop technological processes at the manufacturing stage.

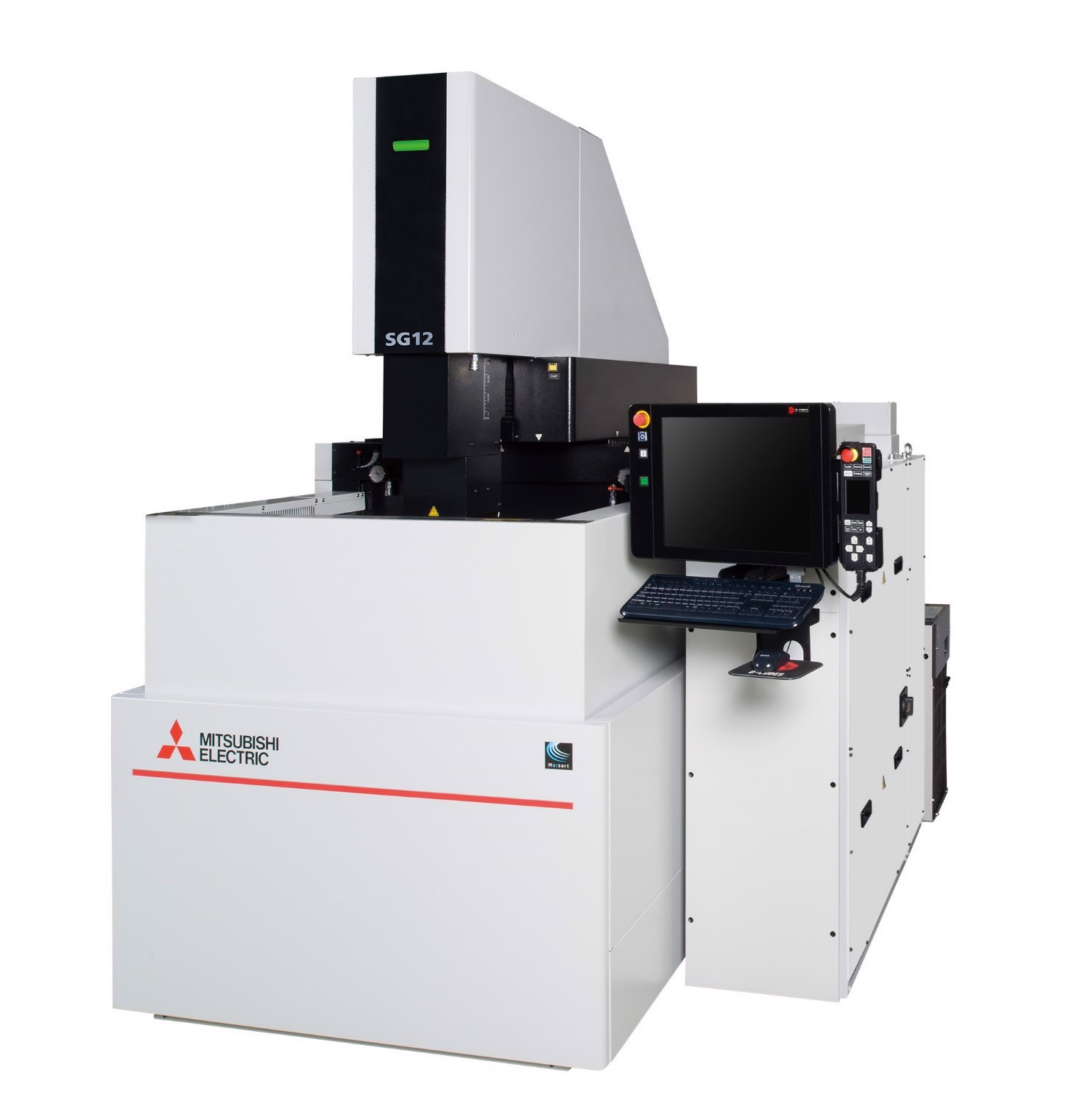

Die sinker EDM- SG series

Die sinker EDM- SG series

EDM processing is regarded as one of the key inventions in the precision machining and machining tool industries, which contributed in the quick advancement of science and technology.

With the help of EDM machines, incredibly complicated forms may be cut automatically, precisely with low-cost, resulting in significant gains in accuracy, quality, productivity, and profitability.

The successful implementation of "forward-looking AI technologies" like Maisart or D-CUBES is a necessary step to keep up with the tremendous pace of change in the modern world. Therefore, Mitsubishi Electric is convinced that it can offer products that are powerfully efficient and exceptional features to satisfy each product's exacting specifications.

Ms. Le Quynh Lam-Secretary of Southern VASI presented Overview of Vietnam Association of Supporting Industry.

Mitsubishi Electric VN recently partnered with the Vietnam Association of Supporting Industries (VASI) to organize a conference with the theme "Make connections, create the future". The conference's goal was to help Vietnam's supporting industries in expanding and becoming a significant link in the global supply chain.

Understanding the essential of utilizing innovative technologies in production, Mitsubishi Electric and VASI together brought the following values to the conference:

- Mitsubishi Electrical Discharge Machines' solution.

- Discussing the future direction and vision of the supporting industry.

- Sharing the ability to successfully navigate challenging market conditions.

- Connecting FDI businesses with Vietnamese ones along the value chain.

Mitsubishi Electric Vietnam, Dynamo Vietnam, Yuwa Vietnam and VASI South shared and exchanged at the conference.

Talk Show on the subject of "THE LINKAGE BETWEEN FDI AND VIETNAMESE ENTERPRISES IN SUPPORTING INDUSTRIES SUPPLY CHAIN" was well received by all guests, and positive remarks and responses were widely disseminated.

Guests participated in Q&A on talk shows.

Additionally, the sharing of knowledge and technology production solutions will help the business community in removing manufacturing bottlenecks now in place and advancing the objective of product standardization and precision.

MEVN and guests raised a champagne glass to celebrate the conference's accomplishment.

MEVN and guests on gala dinner.

Included, this conference offers the business community and experts the chance to share knowledge and develop workable solutions to implement effective strategies in the general field of industrial production as well as "the fields that are and will be development trends in the future such as: battery manufacturing technology (Li battery), battery cores for electric vehicles, semiconductors, automotive engine gears, optics, aviation, aerospace,,.." according to Mr. Shin Iida Department Manager of Factory Automation Division of Mitsubishi Electric Vietnam.