Control the Operating Costs with Mitsubishi Electric Industrial Robots

What makes industrial robotics a prevailing trend for manufacturing businesses in today's era?

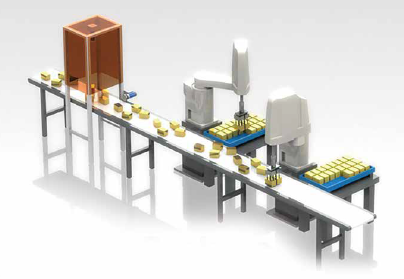

In the fiercely competitive landscape of industrial automation, optimizing operating costs while ensuring product quality has become a significant challenge for every business. Therefore, the most notable transformation trend is a strong investment in Robotics. Mitsubishi Electric Industrial Robots, pioneering in integrating intelligent AI technology, emerge as a fitting solution for manufacturing businesses with numerous advantages.

1. LABOR COST SAVING

- Increased labor efficiency: Mitsubishi Electric Industrial Robots alleviate pressure on employees by swiftly and accurately performing repetitive tasks, allowing workers to shift towards more creative and managerial roles.

- Continuous and non-stop operation: The robot's ability to work continuously enhances production continuity and reduces costs related to labor downtime.

- Minimization of errors due to human factors: Robots are unaffected by human factors such as fatigue or inattention, minimizing product errors and repair costs.

2. INFRASTRUCTURE COST SAVING

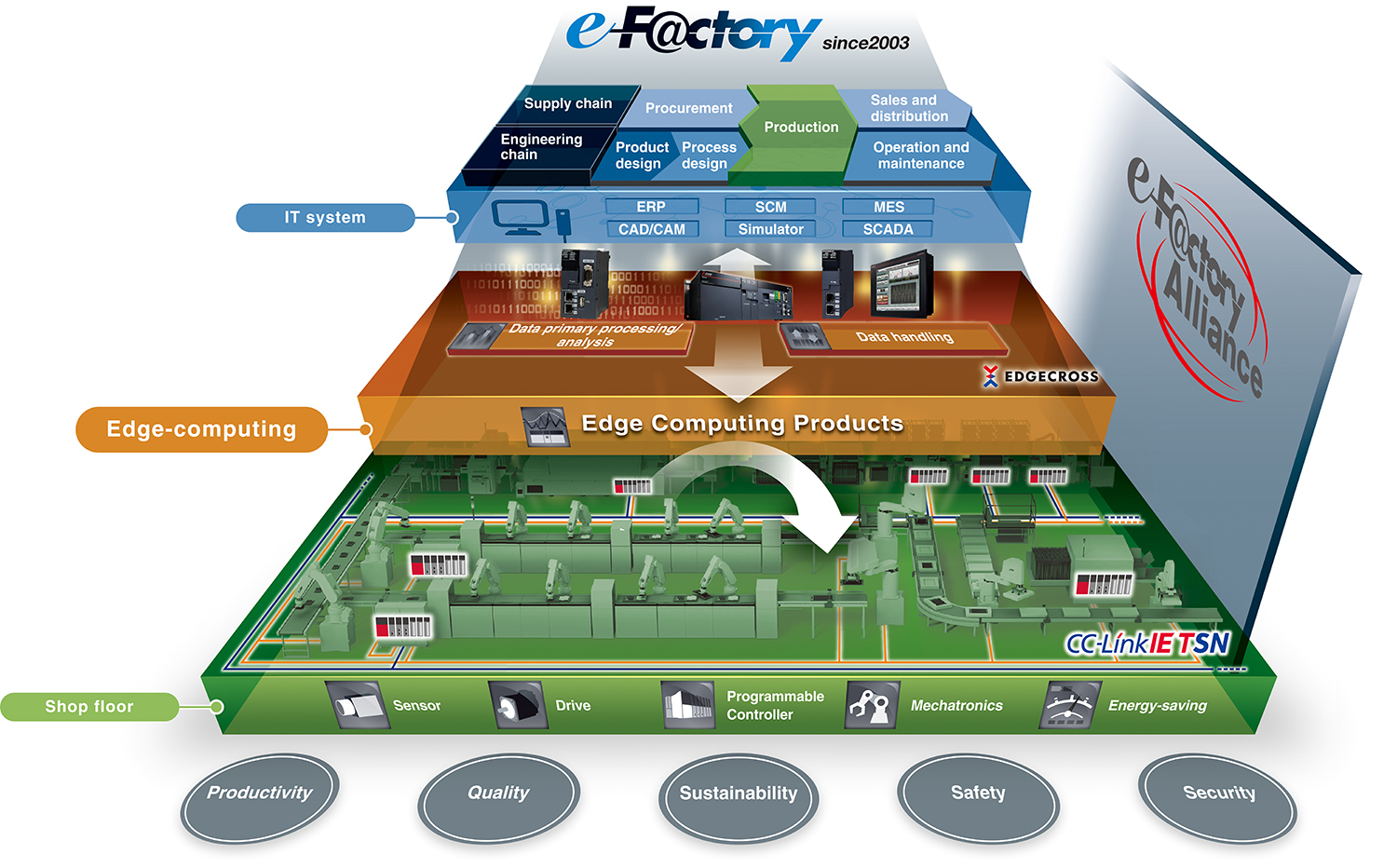

Easy integration into the current system: The flexible design of Mitsubishi Electric Industrial Robots facilitates seamless integration into existing production systems without requiring significant expenses for upgrades or infrastructure changes.

Utilization of various industrial communication methods like CC-Link, MES Interface, SCADA, etc. enables quick connection to the current automated control system. Additionally, Mitsubishi Electric provides accompanying control devices and peripherals, ensuring the system meets diverse customer requirements.

3. MANAGEMENT COST SAVING

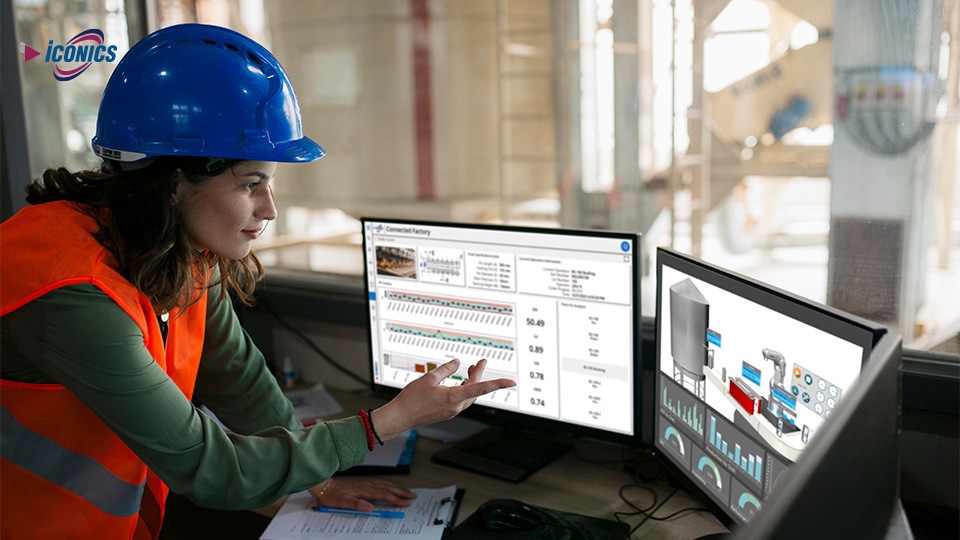

Remote factory management and monitoring

Data on the operations of Mitsubishi Electric Robots are stored in the central data system. Managers can remotely monitor and control them through the Genesis64 software, reducing management costs and enhancing flexibility in adjusting performance according to seasonal demands.

4. TIME SAVINGS IN PRODUCTION & OPTIMIZING EFFICIENCY

High-speed and multitasking operations: Mitsubishi Electric Robots operate at high speed (maximum cycle speed up to 0.29s), ensuring stability and increasing output to quickly meet orders without relying on human factors. Simultaneously, the robot optimizes the production process, reducing waiting times between stages in the production line and flexibly performing intricate tasks simultaneously.

5. ENSURING QUALITY

Precise operations: With accuracy up to 0.01mm, Mitsubishi Electric Robots ensure precise and uniform quality, meeting stringent production requirements.

6. MAINTENANCE COST SAVING AND EXTENDING LIFESPAN

Preventive and predictive maintenance: Integrated with the Smart Plus card, the robot can predict its operating status, allowing proactive maintenance to reduce production downtime and increase system efficiency.

Mitsubishi Electric Industrial Robots are not just tools for optimizing operating costs but also reliable partners in ensuring production quality and efficiency. With the integration of intelligent AI technology, high speed, precision, and predictive maintenance capabilities, Mitsubishi Electric Industrial Robots are a suitable choice for businesses looking to enhance competitiveness and take control of operating costs.