Conference On Smart Manufacturing Solutions - Experiences From The Business Community

On June 28th, Mitsubishi Electric Vietnam participated in sharing and discussing at the smart manufacturing solutions conference in Ho Chi Minh City. The conference was organized by the Management Board of the Ho Chi Minh City High-Tech Park and the Ho Chi Minh City Department of Science and Technology.

Giving the opening speech at the conference, Mr. Le Quoc Cuong, Deputy Head of the Management Board of the Ho Chi Minh City High-Tech Park, emphasized that with the continuous development of the Industry 4.0 era, promoting smart manufacturing is a crucial factor in enhancing the competitiveness of enterprises.

Mr. Le Quoc Cuong delivered the opening speech at the conference

The event attracted many business units to share and discuss, aiming to find effective and innovative solutions. This was an opportunity for enterprises to connect, learn, and apply technological advancements to their production processes.

Accordingly, the Ho Chi Minh City Department of Science and Technology introduced preferential policies to create favorable conditions for businesses, investors, and individuals participating in innovation activities in the area; and also addressed any difficulties in the business development process.

Ms. Nguyen Thi Kim Hue, Deputy Director of the Ho Chi Minh City Department of Science and Technology, shared the department's orientations and business support policies at the conference.

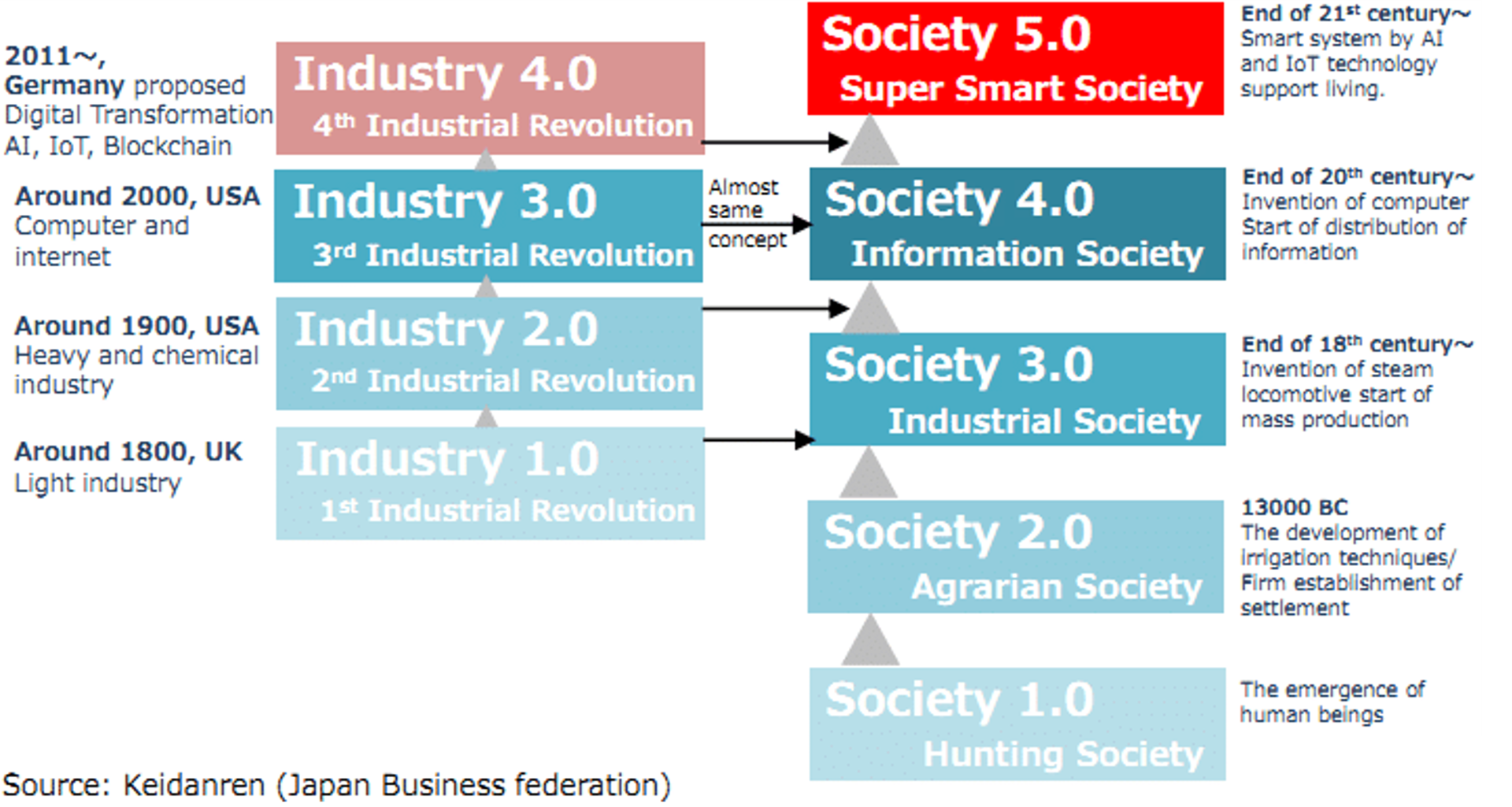

At the conference, Mitsubishi Electric Vietnam presented automation solutions, data centers, and the group's digital technology to serve society 5.0 in the future.

Mr. Pham Phan Anh, Factory Automation Solution Sales Engineer at Mitsubishi Electric Vietnam, shared: “Since launching our "e-F@ctory" concept of data-enabled smart manufacturing in 2004, we have introduced more than 10,000 e-F@ctory solutions around the world. We are now taking the e-F@ctory concept even further. We reproduce virtual factories and virtual production facilities on edge computers and in the cloud. And, on top of that, we leverage data from real production sites to enable evolution of product lifecycles. In this way, we create new values and contribute to customer profits and award to a sustainable society.”

The concept of Society 5.0 was shared, along with optimal solutions from company

In further discussions, Mr. Pham Phan Anh shared the difficulties and challenges in the process of developing smart manufacturing for businesses.

Discussion Question: Despite the many benefits, developing smart manufacturing faces difficulties and challenges for businesses. Could you please share some difficulties in the process of conceptualizing and creating smart manufacturing at Mitsubishi Electric?

Mr Pham Phan Anh shared:

“We must recognize that Digitalization of production or further Digital Transformation of production is a process rather than a definite destination. At Mitsubishi Electric, we have hundreds of factories and production facilities worldwide, but we still constantly improve our capabilities and apply our own technologies to achieve short-term goals and pursue long-term goals like carbon neutrality or Netzero.

In reality, we have faced many difficulties in the production digitalization process in terms of overall resources (Human resources, Financial resources, Technology). Therefore, local businesses and startups may face more difficulties.

However, we must see the global trend of choosing Sustainable Manufacturing. Businesses in Vietnam (from small and medium enterprises to large corporations) should follow the common global rule. With our experience and technology, Mitsubishi Electric always accompanies schools, businesses, and society through specific actions: Sponsoring labs for schools and high-tech parks, sponsoring STEM rooms for primary schools, organizing automation and sustainable initiatives contests.

Additionally, we are ready to share ideas and methods to apply technology to the digitalization process of production such as:

- Using artificial intelligence (AI) to optimize production, predict material demand, machine faults, and production schedules.

- Applying IoT to remotely monitor and manage, helping businesses quickly respond to incidents.

In my opinion, technology is just a tool to realize the goals in Digitalized production, serving humanity and achieving goals like Society 5.0 as I mentioned above.”

The conference brought many values and new perspectives to the participants. Mitsubishi Electric Vietnam will continue to accompany businesses through its advanced green products and solutions.

A look back at some images from the conference: