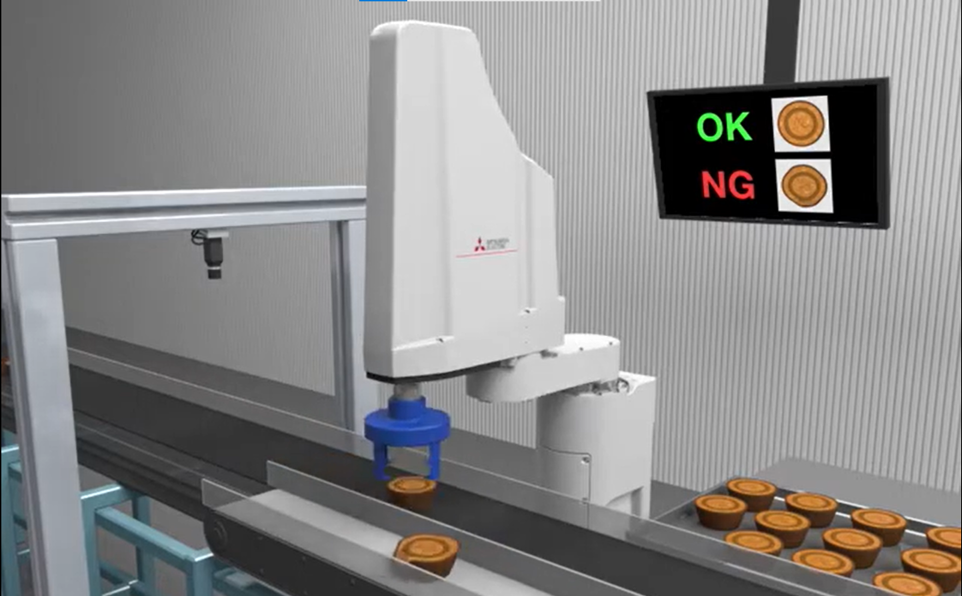

Mitsubishi Electric’s AI Robot – Smartly selecting tart cups and arranging on trays

Mitsubishi Electric's AI Robot is considered a breakthrough device, marking an important step forward in the food production industry, where automation and the application of artificial intelligence blend flexibly and intelligently.

1. DESCRIPTION:

- The vision sensor is integrated into the system, helping the robot to identify the color and shape of each cake, then classify cakes that are defective or have substandard shapes.

- The smart grippers mounted on the robot arm will pick up and drop qualified cakes and arrange them nicely and accurately on the tray based on pre-set positions.

- The ability to locate coordinates on a running conveyor belt (conveyor tracking) helps the robot quickly and accurately pick up each cake moving on the production line.

- The soft gripper is specifically designed to pick up food, helping the robot to exert a moderate force during the process of picking up and dropping soft foods, without affecting the shape of the product.

- Operational performance ensures no spillage of lubricant oil/metal filings within the whole process, meeting ISO Cleanroom standards for safety in food production.

2. IDENTIFY DEFECTIVE PRODUCTS QUICKLY AND EFFECTIVELY

With the advanced vision sensor - MELSENSOR 2D integrated into the system, the robot is able to accurately identify the shape and color of each cake, then automatically classify defective or substandard products. Supports the quality control process and effectively selects finished products.

|

Notes:

|

(MELSENSOR 2D helps the food production process become more modern and smarter, while also improving the quality of the finished product since the robot can automatically detect the cakes that do not meet standards of shape and color)

3. AI ROBOT PERFORMS QUICK PICK-AND-PLACE OPERATIONS WITH ACCURACY UP TO 0.01MM

Mitsubishi Electric robots can operate with accuracy up to 0.01mm. Along with the ability to smartly locate coordinates (thanks to conveyor tracking function), the robot can quickly and accurately pick up each cake on the running conveyor, ensuring optimal progress and productivity.

The application of AI Robot with precise operations will help businesses to save costs thanks to the ability to limit errors in the production process. Along with a maximum cycle speed of up to 0.29s, it helps to increase the output and respond to orders quickly without being affected by uneven quality factors. The ability of robots to work continuously also helps to increase productivity and reduce costs related to employee time off.

(Some applications of vision sensor are integrated in production lines with robots, providing 2D image recognition function to help Mitsubishi Electric robots locate the coordinates of the cake running on the conveyor belt, and simultaneously determine the appropriate picking surface to perform accurate pick-and-place operations)

4. ENSURING THE SHAPE AND QUALITY OF SOFT FOODS

|

The robot is equipped with a smart gripper made from soft rubber material and specifically designed to operate safely in food production:

|

5. ENSURE FOOD SAFETY WITH AI ROBOT THAT MEETS CLEAN ROOM STANDARDS

Thanks to the ability to operate without leaking lubricants into the working environment and no abrasion, Mitsubishi Electric Robots meet ISO Cleanroom standards and all other strict standards of safety in food production.

(Mitsubishi Electric Robot cuts cakes with high accuracy and even quality in the food production process at Newtech Limited - United Kingdom. See more in the article here)

6. CONCLUSION:

The benefits of AI Robot solutions from Mitsubishi Electric will not only help businesses to increase productivity but also reduce errors in the production process, bringing great benefits to the food industry, while providing safe, qualified, and consistent products to the market. This is an important step forward in industrial automation systems, opening up new prospects for sustainable and efficient development in the food production industry.